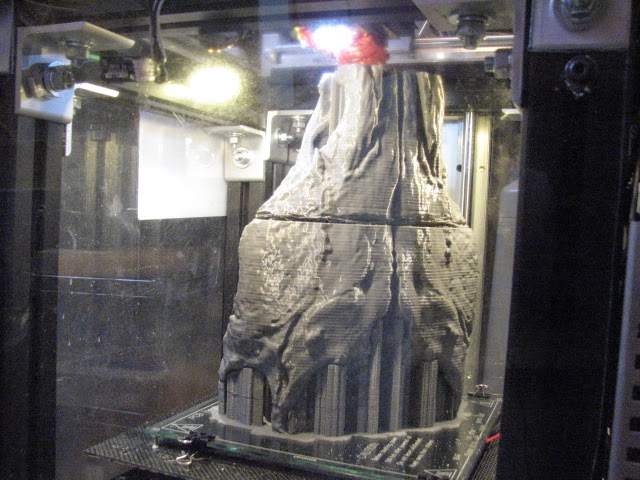

I found that printing the skull in one piece to be rather impractical. It takes over 3 days, and the longer the duration of the print the more chances to have a failure. Also, the standing-up position requires a lot of supports that eventually will become waste. So I have split the skull into two halves - front half and back half - and print them based on the flat 'cut' surface. It cuts the print time to about two days, one per half, and had much less waste and much more mechanical stability during the print. So here is the view of the first front half through the glass build plate before it was removed.

Of course, after you print two halves you have to glue them together - superglue to the rescue (again).

The assembled skull is really awesome - like an alligator I have requests for about 5 of these already. Here is a couple of movie clips showing the machine in action printing these half-skulls:

As far as scanning, that is proceeding with about two bones per week being scanned. We have just sent up the second shipment of bones to the U of Alaska, Fairbanks, to Pat Druckenmiller. His graduate student, Eric Meitz, will be writing up the classification of this animal as a Master's theses. I am only sending up scanned bones so we can make copies down here as desired.

As for grinding out bones, we have found a very nice combination. A couple of months ago we discovered a rounded shell freed by an errant hammer blow. it wasn't quite like an ammonite nor nautiloid. After preparation, it appears to be some type of a slipper snail. And in the open of the skull we found two centrums and two ammonites! very cool combination

Last of all , I have now prepared the fifth (5!!) braincase. This one is more broken than the others, having lost most of one side. However this opened up the brain chamber and allowed me to almost fully prepare the hole that the brain sat in. It is amazing how big the hole is inside one of the braincases!

Last of all, my wife Peggy and I will be taking an extended trip to Alaska starting in mid-May. So I may have one more posting before then. I don't intend to make this blog a travelogue, so I'll limit my posting to fossils we find during the trip .

Sincerely, Greg Carr